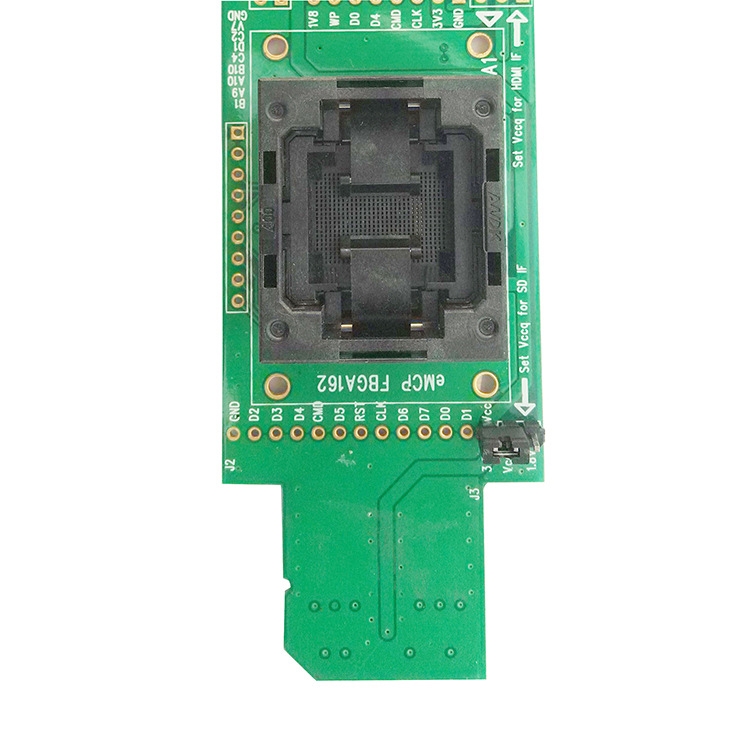

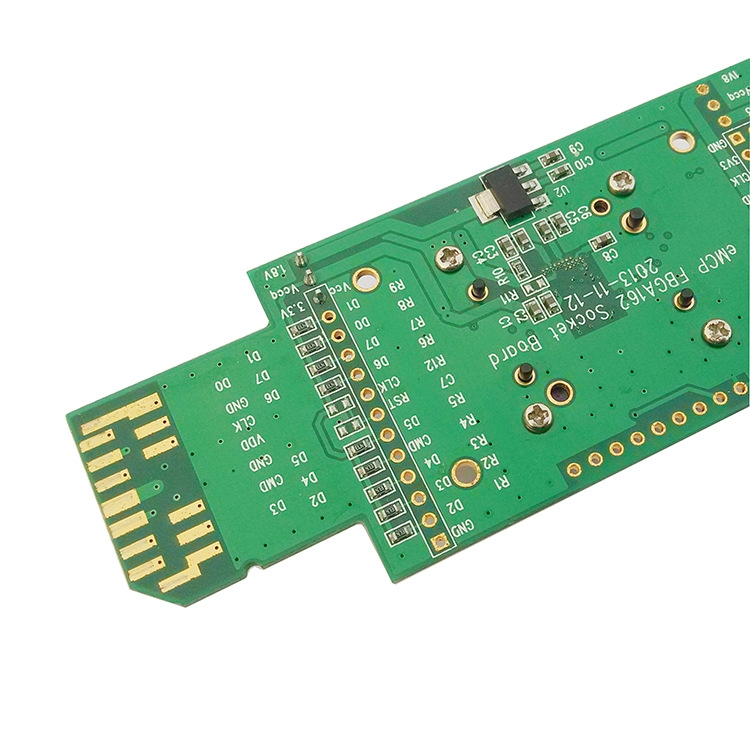

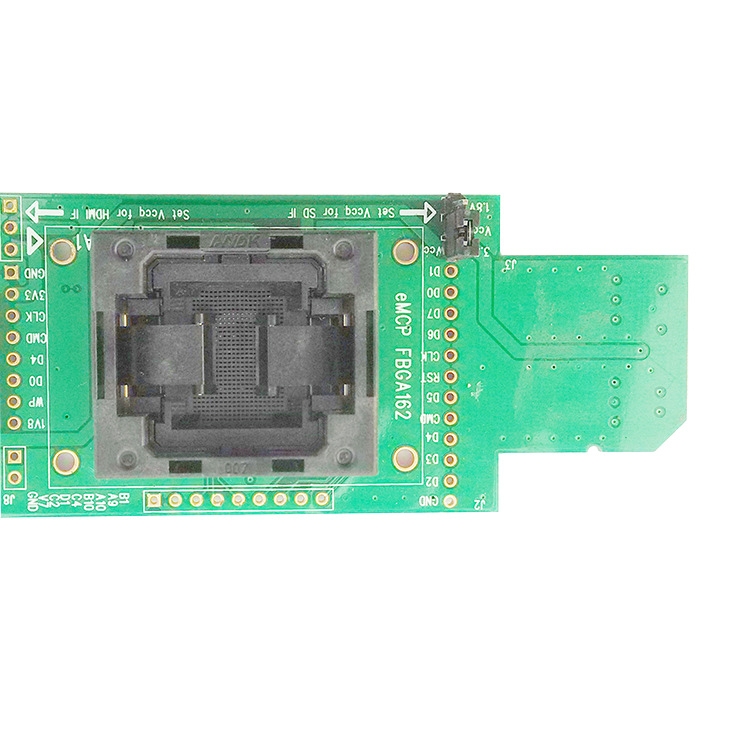

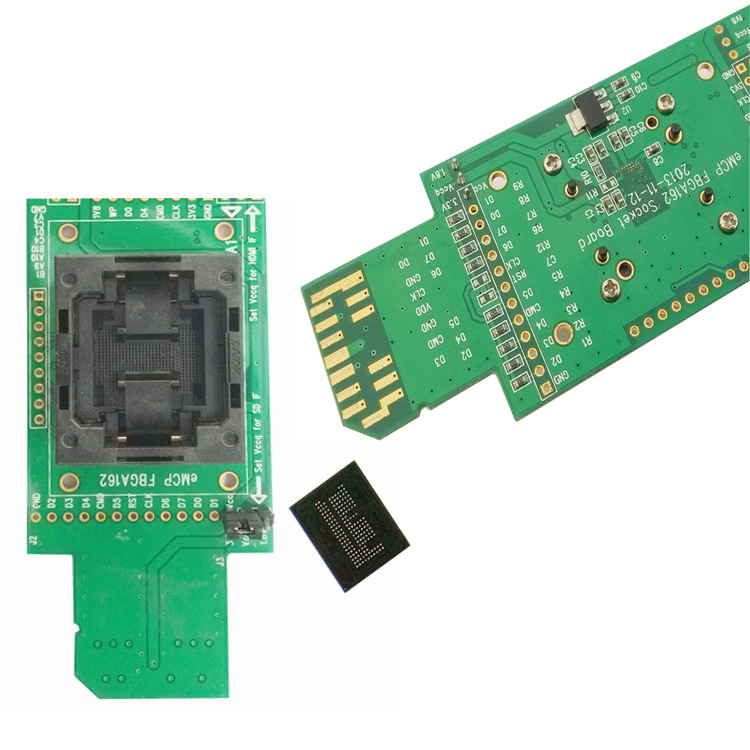

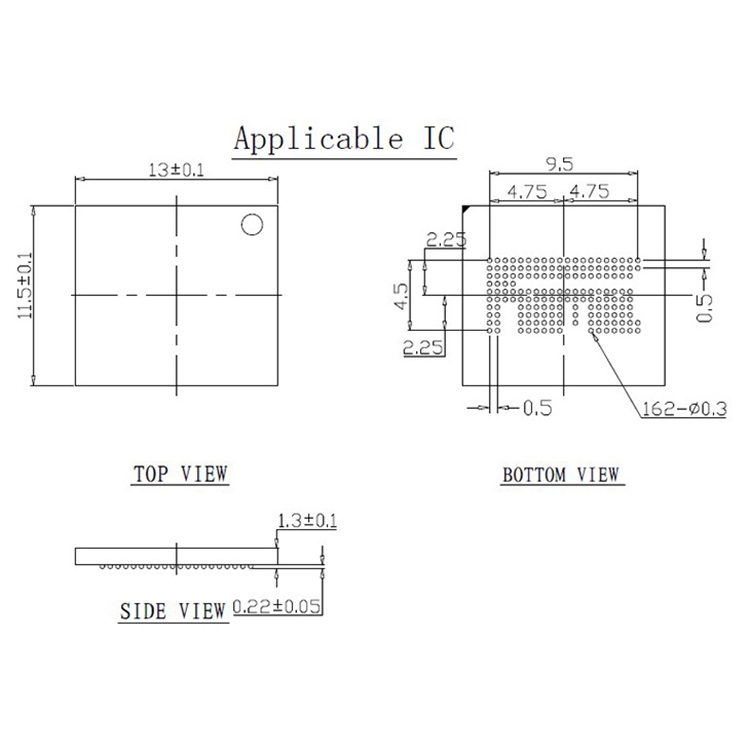

EMCP162 186 Downward Pressure Shrapnel To SD Interface Test Socket Burner Programmer

EMCP162 186 下压弹片转SD接口测试座 烧录器 编程器

条码:6922081615685

HSCode:90329000

批量修改原始型号

|

SKU:

EMCP162 186 Downward Pressure Shrapnel To SD Interface Test Socket Burner Programmer EMCP162 186 下压弹片转SD接口测试座 烧录器 编程器 条码:6922081615685 HSCode:90329000 批量修改原始型号 |

采购:Dani

编辑:Shadow

产品经理:Maura

|

| Package weight |

|